CIRCULÉIRE Innovation Fund Awardees (2020 – 2022)

CIRCULÉIRE’s overarching objective

between 2020-2022 is to source, test,

finance, and scale, circular

manufacturing systems, supply chains

and circular business models

CIRCULÉIRE is the first cross-sectoral industry-led innovation network dedicated to accelerating the net-zero carbon circular economy in Ireland. CIRCULÉIRE is a €4.5m public- private partnership co-created by Irish Manufacturing Research (Secretariat), and three Strategic Partners; the Department for Environment, Climate and Communications (DECC), Environmental Protection Agency (EPA), EIT Climate-KIC and a growing cross-sectoral network of Industry Members.

CIRCULÉIRE’s overarching objective between 2020-2022 is to source, test, finance, and scale, circular manufacturing systems, supply chains and circular business models to deliver significant reductions in both CO2 emissions and waste across our Industry Membership over the programmes’ lifespan.

Below is an overview of the circular economy innovation demonstration projects awarded funding from CIRCULÉIRE’s ring-fenced innovation fund to date:

1: LLLB Centre of Excellence (2020)

Project Title: LLLB Centre of Excellence

Project Short Title or Acronym: LLLB-CE

Number of Partners

including the Lead Partner: 3

Project Duration: 12 months

(in whole months)

Project Lead /Coordinator: WEEE Ireland

Partner #1: KMK Metals Recycling

Partner #2: Wisetek

Solutions Awarded: 2020

LLLB-CE Innovation Demonstration Summary

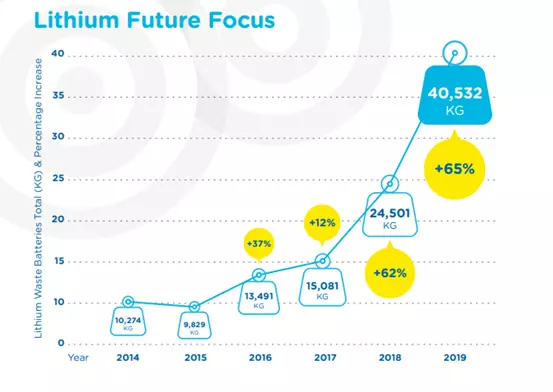

Long-Life Lithium Batteries (LLLB) are a future resource for a more circular economy in Ireland.

LLLBs, sourced from Electric Vehicles (EVs), other mobility applications, IT and energy storage systems, that have reached the end of their first life (typically 7-10 years in an EV), can be tested, stabilised & repurposed for alternative applications such as additional power storage systems. There are currently some early programmes establishing pilot projects in Norway, Italy, the Netherlands and Switzerland but there are no facilities in Ireland undertaking this at present.

The goal of LLLB-CE is to research and develop a safe and circular LLLB management system in Ireland; enabling secure removal, collection, sorting and discharging of these waste batteries which can be repurposed as second life energy storage batteries or other applications, to be used again in Ireland.

Developing this process, training more people in Ireland to handle LLLB environmental management as well as connecting and developing expertise will support the establishment of a collaborative knowledge cluster; A Battery Centre of Excellence. It will help create employment opportunities across the sector and encourage training pathways for circular economy upskilling of operatives currently working in the material sorting and recycling sector in Ireland.

For further information on the LLLB CE Innovation Demonstration Project see the open-access case study available here

2: White Goods Repair Skillset for a Circular Economy (2020)

Project Title: Skillset for a Circular Economy

Project Short Title or Acronym: Skillset

Number of Partners

including the Lead Partner: 3

Project Duration: 12 months

(in whole months)

Project Lead /Coordinator: WEEE Ireland

Partner #1: Fastrack into IT (FIT)

Partner #2: White Goods Association (WGA)

Solutions Awarded: 2020

Skillset Innovation Demo Summary

Repair can be considered one of first and most preferred methods in the WEEE circular economy pathway; to prolong the use phase as it preserves the original state, embedded energy and material of a product. Repair can extend the lifecycle of the product for an initial user or support more second life reuse with one or more end users. If eco-design and vailability of spare parts are crucial, to ensure the lifespan of an appliance can be extended, then the availability of repair skills and trained repair technicians is a critical central component which is currently lacking in Ireland.

The Skillset innovation demonstration project (Circular Economy Skills Initiative) is a collaboration between WEEE Ireland, in partnership with FIT, an industry-led training initiative and registered social enterprise not for profit organisation (www.fit.ie), and the White Goods Association (WGA), an IBEC coordinated industry trade association which represents most of the major manufacturers and distributors of white goods products in Ireland.

This project is unique in that it has industry wide support and input. The White Goods Association members inputted into the Skills Needs Analysis which was undertaken as part of this, and which determines the skills required and training modules to be undertaken by the trainees. This training is also one of the first to include a Circular Economy/Sustainability module as an integral part of the course.

The Circular Economy Skills Initiative project aims to tackle the skills and training bottleneck that exists and help establish more repair and reuse specialists in the white goods sector through circular economy skillset training and the development of formal QQI Accredited appliance repair qualifications in Ireland.

As of July 2021, applicants for The Circular Economy Skills nitiative are seeking applicants to the training programme which can be viewed here – https://fit.ie/circular-economy skills-initiative/

For further information on the White Goods Repair Skillet Innovation Demonstration Project see the open-access case study available here

3: Advanced Robotics to capture Critical Raw Materials in WEEE recycling for a Circular Economy (2021)

Project Title: Advanced Robotics to capture Critical

Raw Materials in WEEE recycling for

a Circular Economy

Project Short Title or Acronym: RoboCRM

Number of Partners

including the Lead Partner: 3

Project Duration: 12 months

(in whole months)

Project Lead /Coordinator: FPD Technologies

Partner #1: Robotics & Drives

Partner #2: University of Limerick

Solutions Awarded: 2021

RoboCRM Innovation Demo Summary

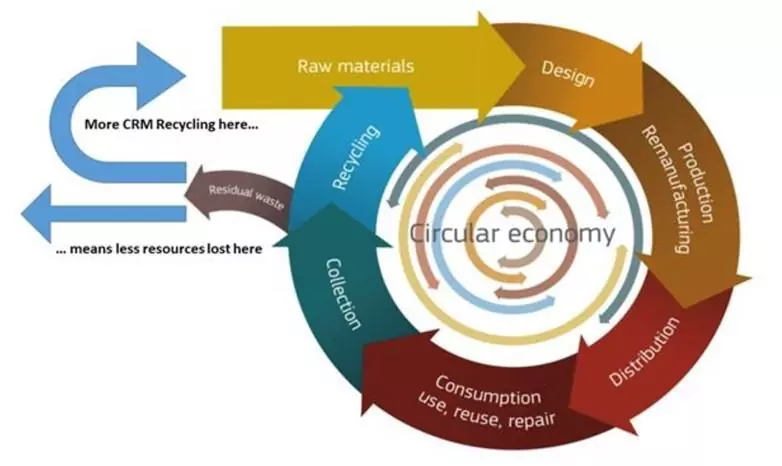

The global economy is at a transition point, moving from the traditional “make, use and discard” linear manufacturing model which has not changed since the Industrial Revolution to a more sustainable and reusable solution that is the Circular

Economy. With an ever-increasing population and limited resources, we need to cease discarding our products and materials when they reach End-of-Life (EOL) and instead “close the loop” by re-using them as raw materials to remanufacture and improve our resource efficiency.

Within the Electrical and Electronic Equipment (EEE) sector, circularity is already evident in the recycling of Waste Electrical and Electronic Equipment (WEEE) devices and products which are End-of-Life. Although WEEE recycling has been in operation for over a decade now, the process is far from effective in recovering all of the necessary resources and materials needed for manufacturing the next generation of devices.

Batteries are one of the richest sources of Critical Raw Materials (CRMs) for WEEE recycling plants. However, more and more appliances nowadays already contain some form of integrated battery or power pack which the user cannot easily remove or replace. This means these devices are effectively WEEE once their batteries are used up, and when are sent for recycling. However, the conditions for such an operation are not safe for human operators -we need a flexible, automated system to

address this challenge.

RoboCRM uses non-destructive detection methods (such as computer vision systems) in conjunction with pattern recognition and an artificial intelligence engine to identify and sort batteries and electronics containing batteries from the main

WEEE stream. Once identified and categorised, these battery powered WEEE items can be processed to support greater recovery of raw materials and CRMs. This will help close the loop on this aspect of the WEEE stream.

Recycling of CRMs will enable circular economies in manufacturing

4: Circular Economy & The Power of Many (2021)

Project Title: Circular Economy & The Power of Many

Project Short Title or Acronym: #CEPowerofMany

Number of Partners

including the Lead Partner: 4

Project Duration: 18 months

(in whole months)

Project Lead /Coordinator: Freefoam Plastics Ltd

Partner #1: Mulligan Guttering Ltd

Partner #2: Glenveagh Properties PLC

Partner #3: Shabra Plastics & Recycling

Solutions Awarded: 2021

#CEPowerofMany Innovation Demo Summary

In 2017, packaging waste in Europe reached a record 173kg per inhabitant. If we drill down this figure, construction packaging waste plays a significant part in this.

The purpose of #CEPowerofMany is to develop a take back scheme for all the materials that are delivered for an installation of roofline building products. These materials are delivered to a construction site for a new or existing house, but do not form part of the end installation. This includes minor leftover parts of the actual product installed. It also includes protective packaging that these products are wrapped in to ensure they are clean and fit for purpose when they arrive on site.

As part of the project Freefoam will review its packaging and look to redesign the methods and materials used to aid in the recovery and reuse process. They will also explore the potential for other contractors on the construction sites to put their packaging materials into the same take back supply chain if the materials are compatible. Also, Freefoam will partner with Shabra Plastics to develop a closed loop system from Freefoams production plant in Cork to Shabras plant in Monaghan, for all PE-LD and cardboard that flows into Freefoam.

5: Sustainable Use of Carbon Contributes to Environmentally Sustainable Systems (SUCCESS) (2021)

Project Title: Sustainable Use of Carbon Contributes

to Environmentally Sustainable Systems

Project Short Title/ Acronym: SUCCESS

Number of Partners: 3

Project Duration: 9 months

Project Lead: Dawn Meats

Partner #1: BHSL

Partner #2: University of Limerick

Funding Awarded: 2021

SUCCESS Summary

Dawn Meats is one of Europe’s largest food processing companies producing 430,000 tonnes of added value meat products annually, sourced from over 30,000 farmers. It has carried out an analysis on all by-products derived from the food production business with the objective of quantifying energy levels in animal by-products and sludge. The potential for this green energy married well with the efforts of BHSL (an animal waste to energy technology provider) and researchers at University of Limerick who had already delivered a similar project and commercial success for the poultry sector.

The BHSL technology is capable of being used on a small to medium scale level and can extract and convert the energy into a usable form. University of Limerick researchers have been working with BHSL on both the technology and nutrient values derived from the combustion process. This consortium seeks to deliver Ireland’s first circular meat processing demonstration plant extracting maximum renewable energy from processing side-streams and residues while creating a high-value end product to service the growing biofertilizer sector. This project has the potential to transform Ireland’s meat processing sector into a circular economy model bringing benefits to the environment, economy, and society.

6: Upcycled Insulation (2022)

Project Title: Upcycled Insulation

Number of Partners: 4

Project Duration: 12 months

Project Lead: Cirtex

Partner #1: Interior Creations Ltd

Partner #2: Longford County Council

Partner #3: Clare County Council

Funding Awarded: 2022

Upcycled Insulation Summary

Tens of thousands of tonnes of mattresses, pillows, duvets, furniture, and postproduction waste, like offcuts from those industries, are incinerated each year. Ireland has no answer to upcycling this end-of-life material.

Cirtex Ltd is a new Irish company that can turn this soft padding material into insulation and other useful products which can be further upcycled when they reach their “End of Life”. Cirtex will demonstrate with Clare and Longford Co Councils that these materials can be collected from the public in a clean and effective manner. Cirtex will also work with a bed manufacturer and recover postproduction waste and then convert these materials into viable Insulation Products for housing and padding for the furniture and bedding industry.

Following a successful innovation demonstration, this project will have the potential to be scaled up and rolled out across a broader cohort of recycling centres and take-back schemes for retailers. In addition to being a direct diversion from landfill and incineration, it is also providing a sustainable alternative in the same quantities to existing building insulation, furniture and bedding manufacturers for their production process. It will also create industrial symbiosis by providing a viable upcycling outlet for used material and providing green alternatives to their supply chain.

7: Circular by Design (2022)

Project Title: Circular by Design

Number of Partners: 2

Project Duration: 12 months

Project Lead: Design & Crafts Council of Ireland

Partner #1: National College of Art and Design

Funding Awarded: 2022

Circular by Design Summary

The global textiles and apparel industry is the joint third highest emitter of greenhouse gases globally 1 and operates in an almost completely linear ‘take-make-waste’ system. To address this challenge, The Design and Crafts Council Ireland (DCCI), the National College of Art and Design (NCAD) and the Creative Futures Academy (CFA) have come together to design and launch ‘Circular By Design’; a first-of-a-kind training programme that supports textile and fashion designers, brands and manufacturers to make the transition to circular practices in every step of their design practice, value chain and business model.

In its first pilot year, Circular By Design will equip 7-10 Irish textiles and apparel businesses with the knowledge and skills needed to design materials, products and businesses for circularity. Upon completion, participants will have a foundational knowledge of the circular economy, and will have redesigned their value propositions, materials, products, services, and business models according to circular principles.

It will also connect Irish designers, brands, and manufacturers with peers, experts, and innovators, both nationally and internationally, through a Community of Practice (CoP). Finally, the project will demonstrate and showcase the power of circular design within Ireland’s textile and apparel industry, by developing and disseminating best practices through an Innovation Festival and Toolkit.

8: Do more with Less (2022)

Project Title: Do More With Less

Number of Partners: 3

Project Duration: 12 months

Project Lead: Farrell Furniture

Partner #1: GMIT – Letterfrack

Partner #2: Office of Public Works

Funding Awarded: 2022

Do More with Less Summary

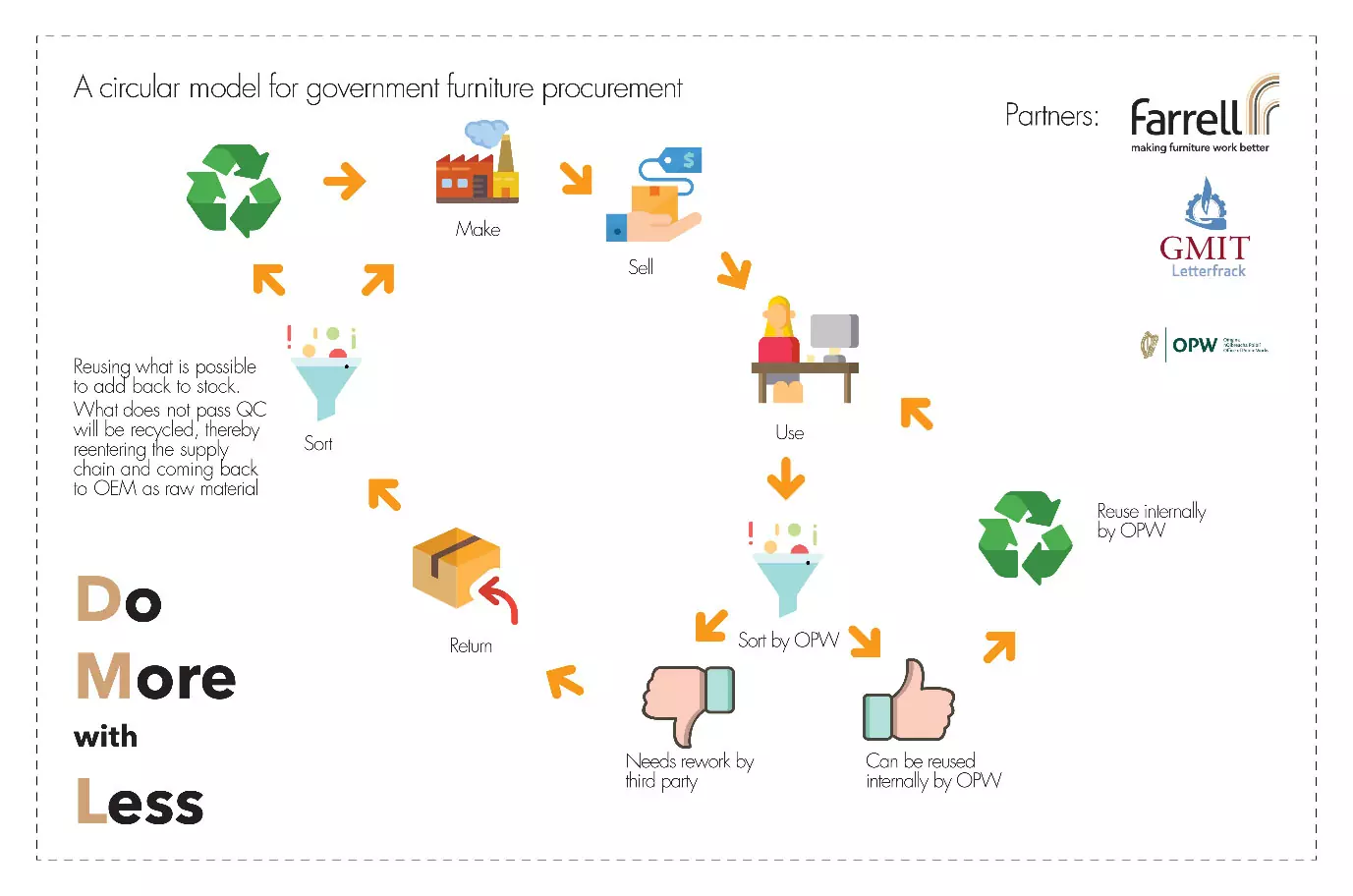

A collaborative furniture take-back and remanufacturing scheme that moves Government from green procurement to circular procurement. The goal of this collaboration is to develop and implement a series of small-scale demonstrations of circularity within the public sector.

There are two streams within the project. In the first, obsolete office furniture, that would have been manufactured by Farrell in the mid 2000’s, will be taken back from the Office of Public Works (OPW) and repaired, remanufactured and then redistributed throughout the public sector. In the second stream, a series of classic chairs that are no longer manufactured, will be studied and reverse engineered by GMIT. This will allow their repair and reuse, keeping this classic price of Irish Design in use for many years to come.

The project will demonstrate, using these two examples, how a take-back system can operate across a variety of divergent products and document the process of moving to a more circular procurement model.

9: MEDAL: MED Devices A new Life (2022)

Project Title: MEDAL: MED Devices A new Life

Project Short Title/ Acronym: MEDAL

Number of Partners: 3

Project Duration: 12 months

Project Lead: Offerre

Partner #1: Peregrine Technologies Ltd

Partner #2: University of Limerick

Funding Awarded: 2022

MEDAL Summary

The health sector is responsible for 4.6 % of global greenhouse gas emissions, and approximately the same proportion of pollutant air emissions. Part of the reason for this high level of emissions is due to an increasingly reliance on single-use disposable devices, particularly in high-income countries.

Experience to date supports the proposition that the volume of individual producer wearable medical devices is insufficient to cost justify standalone take-back, deposit, or send back schemes. Several producers have discontinued take-back schemes for cost reasons. There is support from producers for a cost-efficient take-back and reprocessing system for these devices, extending product use, in compliance with reprocessing protocols and maintaining product integrity.

This take-back system will be designed using the principles of high performance; convenience; producer engagement and system integrity, taking into consideration the requirements of key stakeholders and regulators. Whilst there is general acknowledgement that a circular model must value public health and sustainability, the device consumer is a critical link in achieving high recycling rates for medical devices.

For this reason, this research will address consumer behavioural routines relating to disposal practices. The demonstrator model will assess automation solutions for cleaning and de-manufacturing and support the circular design of products and packaging. The system will provide a cloud-based platform allowing device consumers to interact with the producers of these devices.

10: C-SUP | Circularising Single-Use Plastic

Project Title: C-SUP | Circularising Single-Use Plastic

Project Duration: 8 months

Project Lead: Novelplast Teoranta

Partner : Irish Green Labs; Envetec Sustainable Technologies Limited; CÚRAM,

NUI Galway; Technical University of the

Shannon (TUS) Midlands and Connacht &

Ulster RWO)

Funding Awarded: 2022

C-SUP Summary

Within the Irish laboratory ecosystem, large volumes of high-quality carbon-intensive plastic are used extensively. The majority of plastic supplied to labs in Ireland comes from Germany, the UK or the US with most being incinerated in Ireland after a single use. A recent national lab plastics audit completed by NUIG and Irish Manufacturing Research revealed that polypropylene pipette tips are the most common single-use lab plastic items being discarded.

This demonstration project, Circularising Single-Use- Plastic (C-SUP), seeks to speed up the circular evolution of Irish laboratories by demonstrating that single-use polypropylene (PP) labware could become a novel feedstock for Irish recyclers.

This circular solution provides a way for lab workers to reduce the negative impact that their research is having on the environment. Once this idea is disseminated via the Irish Green Labs network to the thousands of Irish labs, the purchasing of recycled PP labware by Irish lab workers, would become ‘the norm’, thus, boosting the local circular economy while also helping to mitigate against Ireland’s GHG emissions.

Under the umbrella of Irish Green Labs, the lead organisation Novelplast Teoranta is partnering with Envetec Sustainability Ltd, and researchers based in the Technical University of the Shannon (TUS) and NUI Galway.